Typical Problems Fixed by Commercial Refrigerator Repair Professionals in Toronto

Typical Problems Fixed by Commercial Refrigerator Repair Professionals in Toronto

Blog Article

Fixing Industrial Refrigeration Repair Work: Methods for Quick and Effective Fixes

In the realm of commercial refrigeration, the demand for swift and exact troubleshooting methods is vital. When a refrigeration system malfunctions, the consequences can be disruptive and costly to business procedures. Comprehending the typical concerns that pester commercial refrigeration systems and having a toolkit of analysis strategies at hand can make all the distinction in promptly recognizing and remedying issues. As we browse with the complexities of troubleshooting business refrigeration repair work, we will certainly uncover the vital techniques for solving issues effectively, ensuring that services can maintain ideal air conditioning performance and reduce downtime.

Common Business Refrigeration Problems

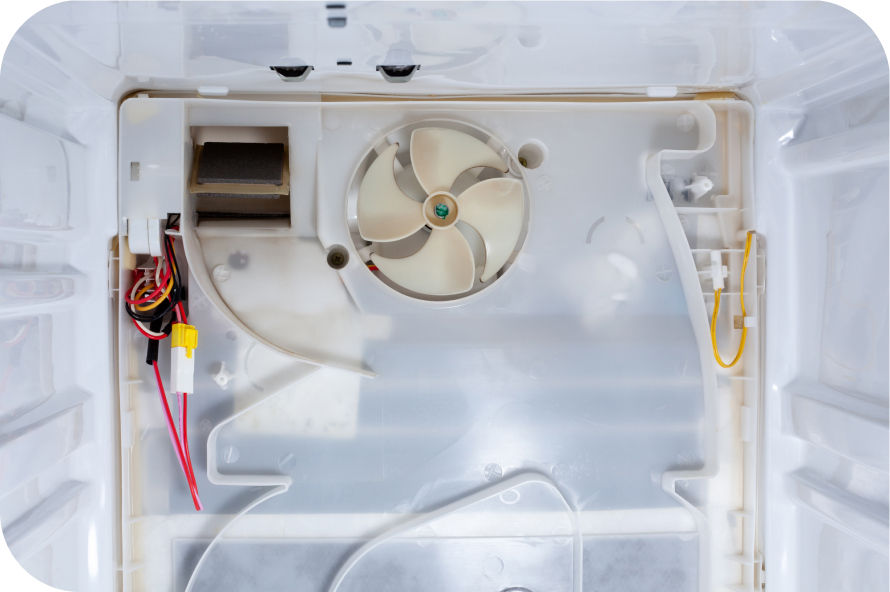

Commercial refrigeration systems generally run into a series of functional issues that can interrupt their efficiency and efficiency. One widespread issue is inappropriate temperature control, which can cause food perishing and waste if not without delay dealt with. This trouble might stem from concerns with the thermostat, evaporator fan, or condenser coils, calling for detailed examination to determine the origin reason. One more common issue is inadequate airflow, commonly triggered by blockages in the vents or a malfunctioning fan. Poor airflow can lead to temperature level disparities within the refrigerator or fridge freezer, influencing the top quality and security of kept products.

Furthermore, refrigerant leakages pose a substantial issue as they not just impact the air conditioning capacity of the system however also contribute to ecological injury. Regular cleaning and upkeep can aid prevent this problem and lengthen the lifespan of the refrigeration system.

Analysis Tools and Techniques

Efficient troubleshooting of business refrigeration systems relies greatly on utilizing specialized analysis devices and techniques to identify and solve underlying issues efficiently. One necessary analysis tool is the multimeter, which helps technicians determine voltage, present, and resistance in numerous elements such as compressors, electric motors, and thaw heating systems. Thermometers are also vital for assessing temperature differentials across the system to identify prospective issues like cooling agent leakages or incorrect air movement. Furthermore, leakage discovery devices like digital leakage detectors or ultraviolet dye packages are vital for finding cooling agent leaks that can cause system inadequacies.

If the system has the appropriate cooling agent cost and recognize any kind of leakages,Strategies such as stress screening utilizing manifold assesses can determine. Aesthetic assessments of elements for signs of rust, ice, or wear buildup are additionally essential in diagnosing problems. Furthermore, information loggers can be employed to check system performance gradually and detect fads that may suggest recurring issues. By combining these diagnostic devices and strategies, service technicians can effectively fix business refrigeration systems and offer fast and precise repair services, minimizing downtime and guaranteeing optimum system efficiency.

Quick Fixes for Refrigeration Troubles

When encountered with refrigeration issues, specialists can implement fast repairs to deal with common concerns quickly and effectively. If the refrigeration unit is not cooling down properly, examining and adjusting the thermostat setups may supply a fast service prior to even more thorough troubleshooting is required. By applying these fast fixes, professionals can attend to common refrigeration issues efficiently and keep business refrigeration systems running smoothly.

Preventative Upkeep Tips

Carrying out a proactive upkeep routine is essential for making certain the longevity and optimal performance of business refrigeration systems. Regular maintenance not just aids avoid pricey malfunctions but likewise ensures that the devices runs effectively, conserving power and minimizing general operating expense. Right here are some preventative maintenance ideas to maintain business refrigeration systems running smoothly:

Inspect and Change Filters: Dirty filters can limit airflow, making the system job tougher and potentially causing damage. Inspect and replace filters frequently to stop issues.

Inspect Seals and Gaskets: Leaking seals and gaskets can result in temperature variations and energy wastage. Changing and evaluating harmed seals can help keep regular temperatures.

Specialist Assistance and Solutions

To keep the ideal performance attained through normal preventative maintenance, looking for expert YOURURL.com support and services for commercial refrigeration systems is necessary. Expert specialists have the expertise and specialized expertise required to detect and deal with intricate issues successfully. When facing difficult refrigeration problems, counting on specialist support can conserve both time Get More Information and money over time.

Expert solutions use advantages such as access to innovative tools and devices, making certain that repair services are carried out properly. In addition, specialists are educated to stick to industry guidelines and safety standards, reducing the danger of accidents and making sure conformity with lawful requirements.

Conclusion

To conclude, troubleshooting industrial refrigeration repair work calls for a methodical method to recognizing common concerns, utilizing analysis devices and methods, implementing fast fixes, and prioritizing preventative maintenance. Specialist support and services might be necessary for more facility issues - Toronto commercial refrigerator repair. By adhering to these techniques, companies can guarantee their refrigeration systems run efficiently and properly, reducing downtime and potential losses

Recognizing the typical issues that afflict industrial refrigeration systems and having a toolkit of diagnostic methods at your disposal can make all the difference in quickly determining and treating troubles.Reliable troubleshooting of business refrigeration systems counts heavily on utilizing specialized diagnostic Web Site tools and strategies to recognize and deal with underlying problems effectively. By integrating these diagnostic tools and techniques, professionals can effectively fix business refrigeration systems and supply precise and quick repair services, reducing downtime and making certain ideal system performance.

By executing these quick solutions, professionals can attend to usual refrigeration troubles successfully and maintain industrial refrigeration systems running smoothly.

Furthermore, specialist support can help expand the life expectancy of industrial refrigeration systems by identifying possible problems before they escalate.

Report this page